Feature

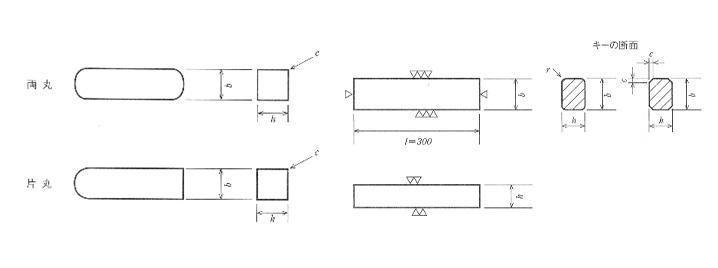

The high strength, impact resistance, and stable transmission capability of the double round key make it an ideal key structure for many heavy-duty and high-precision mechanical equipment. Its design can effectively reduce stress concentration and improve durability, making it suitable for applications requiring high-precision and high-strength transmission.

Single-return keys are widely used in the field of mechanical transmission due to their uniform stress distribution, high torque bearing capacity, and easy installation. They are especially suitable for equipment with high loads, high speeds, and frequent disassembly and assembly. Although its torque carrying capacity is not as good as that of double round keys, its structure is simple, economical and practical, and it is still an important choice in many mechanical designs.

Parallel key is a mechanical key connection method with high degree of standardization, simple structure and wide application, which is suitable for various mechanical transmission equipment. Its efficient torque transmission capability and good shear strength make it the preferred bonding solution in many industrial fields.

Dimensions

Specification

Unit: mm

| Nominal Size of Key b × h |

Key Size |

|||||

| b | h | I | ||||

| Base Size | Tolerance(h9) | Base Size | Tolerance | |||

| 3 × 3 | 3 | 0 -0.025 | 3 | 0 -0.025 | h9 | 8~120 |

| 4 × 4 | 4 | 0 -0.030 | 4 | 0 -0.030 | h9 | 8~120 |

| 5 × 5 | 5 | 0 -0.030 | 5 | 0 -0.030 | h9 | 8~200 |

| 6 × 6 | 6 | 0 -0.030 | 6 | 0 -0.030 | h9 | 8~200 |

| 7 × 7 | 7 | 0 -0.036 | 7 | 0 -0.036 | h9 | 8~200 |

| 8 × 7 | 8 | 0 -0.036 | 7 | 0 -0.090 | h11 | 10~200 |

| 8 × 8 | 8 | 0 -0.036 | 8 | 0 -0.090 | h11 | 10~200 |

| 10 × 8 | 10 | 0 -0.036 | 8 | 0 -0.090 | h11 | 15~200 |

| 10 × 10 | 10 | 0 -0.036 | 10 | 0 -0.090 | h11 | 15~200 |

| 12 × 8 | 12 | 0 -0.043 | 8 | 0 -0.090 | h11 | 15~200 |

| 12 × 10 | 12 | 0 -0.043 | 10 | 0 -0.090 | h11 | 20~200 |

| 12 × 12 | 12 | 0 -0.043 | 12 | 0 -0.090 | h11 | 20~200 |

| 14 × 9 | 14 | 0 -0.043 | 9 | -0.090 0 | h11 | 30~200 |

| 15 × 10 | 15 | 0 -0.043 | 10 | 0 -0.090 | h11 | 30~200 |

| 16 × 10 | 16 | 0 -0.043 | 10 | 0 -0.090 | h11 | 35~200 |

| 18 × 11 | 18 | 0 -0.043 | 11 | 0 -0.110 | h11 | 35~200 |

| 18 × 12 | 18 | 0 -0.043 | 12 | 0 -0.110 | h11 | 35~200 |

| 20 × 12 | 20 | 0 -0.052 | 12 | 0 -0.110 | h11 | 40~200 |

| 20 × 13 | 20 | 0 -0.052 | 13 | 0 -0.110 | h11 | 40~200 |

| 22 × 14 | 22 | 0 -0.052 | 14 | 0 -0.110 | h11 | 50~200 |

| 24 × 16 | 24 | 0 -0.052 | 16 | 0 -0.110 | h11 | 50~200 |

| 25 × 14 | 25 | 0 -0.052 | 14 | 0 -0.110 | h11 | 50~200 |

| 28 × 16 | 28 | 0 -0.052 | 16 | 0 -0.110 | h11 | 60~200 |

| 28 × 18 | 28 | 0 -0.052 | 18 | 0 -0.110 | h11 | 60~200 |

| 32 × 18 | 32 | 0 -0.062 | 18 | 0 -0.110 | h11 | 60~200 |

| 32 × 20 | 32 | 0 -0.062 | 20 | 0 -0.110 | h11 | 60~200 |