Feature

Hexagonal headless conical pipe plug (PT) is a special-shaped closing device. Its main function and application product is to seal pipes or holes to prevent dirt from entering. Pipe plugs are usually designed to be very tight to provide effective sealing performance. If a rubber sealing ring is installed on the thread surface of the pipe plug, the sealing performance will be improved and liquid or air leakage will be prevented. Hexagonal headless tapered pipe plugs (PT) are available in stainless steel, alloy steel, and copper materials. They are used in various industrial pipelines, mechanical equipment, and engineering systems to close holes, pipes, or containers to protect internal components or prevent pollute.

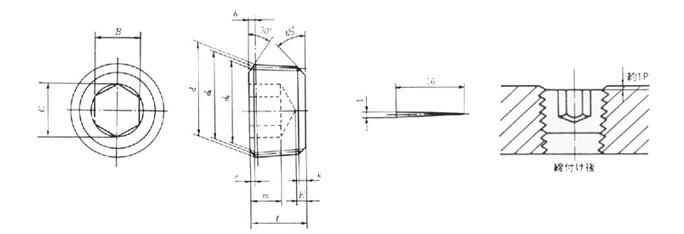

Dimensions

Specification

Unit: mm

| Specification |

PT 1/8 |

PT 1/4 | PT 3/8 | PT 1/2 | PT 3/4 | PT 1 | PT 1 1/4 | ||

| Number of threads (per 25.4mm) | 28 | 19 | 19 | 14 | 14 | 11 | 11 | ||

| Reference Diameter | d | 9.728 | 13.157 | 16.662 | 20.955 | 26.441 | 33.249 | 41.91 | |

| d2 | 9.147 | 12.301 | 15.806 | 19.793 | 25.279 | 31.77 | 40.431 | ||

| d1 | 8.556 | 11.445 | 14.95 | 18.631 | 24.117 | 30.291 | 38.952 | ||

| Reference Diameter The Position of | NO.1 | End Distance | 0.45 | 0.7 | 0.7 | 0.9 | 0.9 | 11 | 11 |

| Tolerance | +11 | +1.5 | +1.5 | +2 | +2 | +2.2 | +2.2 | ||

| 0 | 0 | 0 | 0 | 0 | 0 | 0 | |||

| Hexagonal Hole | Two-Sided Width B | Base Size | 5 | 6 | 8 | 10 | 14 | 17 | 22 |

| Tolerance | +0.10 | +0.10 | +0.13 | +0.13 | +0.23 | +0.23 | +0.275 | ||

| +0.03 | +0.03 | +0.04 | +0.04 | +0.05 | +0.05 | 0.065 | |||

| Diagonal Distance C | 5.9 | 7 | 9.4 | 11.7 | 16.3 | 19.8 | 25.6 | ||

| Depth M | NO.1 | 3.5 | 4.5 | 5 | 6 | 7 | 9 | 10 | |

| NO.2 | 3 | 5 | 5 | 6.5 | 8 | 10 | 10 | ||

| Length ±0.4 | NO.1 | 7 | 9 | 10 | 12 | 14 | 16.5 | 19 | |

| NO.2 | 8 | 11 | 12 | 15 | 17 | 19 | 22 | ||

| Chamfer | Big end E | 0.5 | 0.7 | 0.7 | 1 | 1 | 1.3 | 1.3 | |

| Small end K | 1 | 1.4 | 1.4 | 1.9 | 1.9 | 2.5 | 2.5 | ||

| The thickness of the bottom E (minimum) | NO.1 | 1.5 | 1.5 | 1.5 | 1.5 | 2 | 2 | 2 | |

| NO.2 | 1.5 | 1.5 | 1.5 | 2.5 | 2.5 | 2.5 | 2.5 | ||